Enhancing Product Development with Advanced Plastic Injection Molding Solutions

Enhancing Product Development with Advanced Plastic Injection Molding Solutions

Blog Article

The Future of Plastic Injection Molding: Advancements and fads to See

As the plastic shot molding market progresses, numerous vital trends are arising that promise to reshape its landscape. Automation and smart manufacturing methods are established to boost performance, while the change in the direction of sustainable products shows an expanding ecological awareness. In addition, innovations in 3D printing are leading the means for unmatched style versatility. However, these developments additionally bring forth challenges that call for mindful factor to consider. Comprehending how these elements will certainly engage and influence future practices is crucial for stakeholders looking to browse this transformative duration properly.

Automation and Smart Production

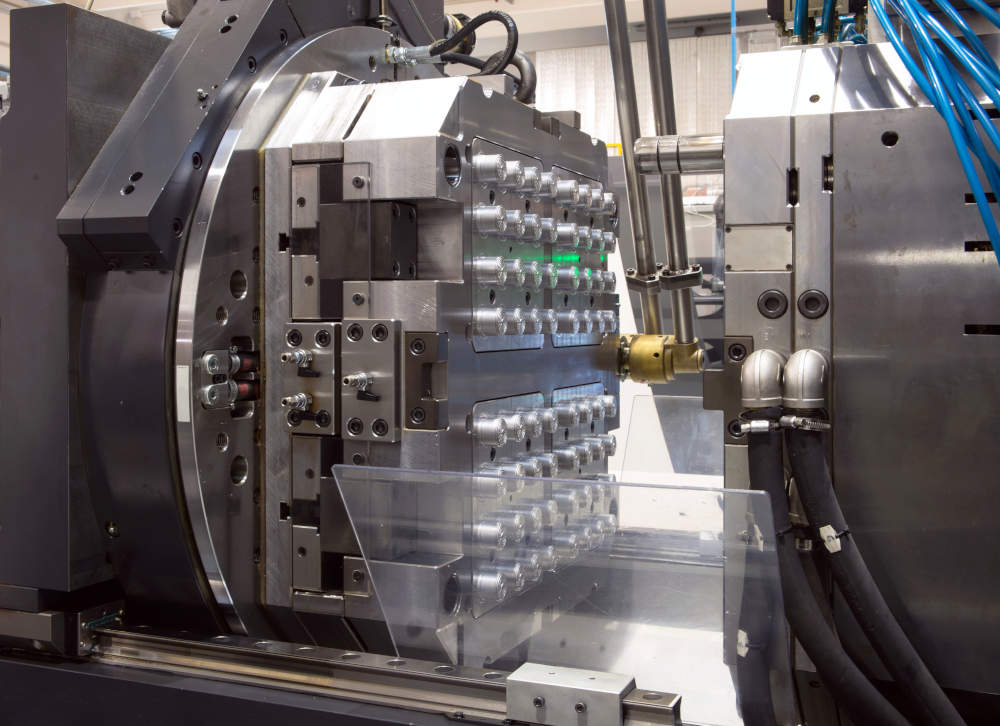

As the plastic injection molding sector develops, automation and smart production are taking spotlight, revolutionizing production processes - Plastic Injection Molding. The assimilation of advanced modern technologies such as robotics, IoT (Internet of Points), and expert system is making it possible for manufacturers to enhance performance, decrease functional expenses, and improve item quality. Automated systems simplify process, minimizing hands-on treatment and enhancing throughput, which is vital in fulfilling the increasing need for rapid manufacturing cycles

Smart making modern technologies assist in real-time monitoring and data evaluation, allowing firms to optimize device efficiency and forecast maintenance requirements. This aggressive approach not only decreases downtime but likewise expands the lifespan of equipment. Additionally, the usage of collaborative robots, or cobots, enhances the versatility of assembly line, making it possible for makers and employees to run alongside safely and efficiently.

The adoption of automation in plastic injection molding is not merely a trend but a tactical imperative for companies aiming to stay competitive in a worldwide market. By utilizing these innovations, producers can accomplish higher precision, decrease waste, and adapt swiftly to changing customer needs, placing themselves for lasting development in a progressively automatic future.

Sustainable Materials and Practices

The press in the direction of automation and clever manufacturing has led the way for a better focus on sustainable materials and practices within the plastic shot molding market. Business are increasingly looking for green choices to standard petroleum-based plastics, resulting in the adoption of bio-based and recycled products. These sustainable materials not just decrease environmental influence however also straighten with customer demand for greener items.

Furthermore, cooperation in between manufacturers, product suppliers, and ecological companies is cultivating technology in the growth of lasting products that satisfy efficiency requirements without jeopardizing quality. As regulations around plastic use come to be more stringent, the market is poised to adapt by accepting these lasting methods, guaranteeing long-term viability and reducing dependence on non-renewable sources. The combination of sustainability into plastic shot molding is not simply a pattern; it is ending up being a vital component of company duty and operational excellence.

Breakthroughs in 3D Printing

Current developments in 3D printing technology are substantially transforming the landscape of plastic injection molding. Difficult or once tough official site to accomplish via standard methods, the assimilation of additive manufacturing procedures allows for the rapid prototyping of complicated geometries that were. This capability not just accelerates item development cycles however additionally minimizes product waste, lining up with the expanding demand for lasting manufacturing techniques

Furthermore, the appearance of hybrid manufacturing strategies, which combine 3D printing and shot molding, supplies producers the capability to develop elaborate layouts while maintaining the effectiveness of mass manufacturing. This approach allows the manufacturing of customized parts tailored to particular consumer needs without sacrificing the speed and scalability that shot molding gives.

Additionally, developments in products, such as high-performance polymers and compounds especially created for 3D printing, are boosting the functional capabilities of printed elements. These products can hold up against better stress and exhibit enhanced thermal buildings, making them ideal for more demanding applications.

As 3D printing remains to develop, its combination into plastic injection molding processes promises to enhance productivity, decrease prices, and foster innovation in product layout, placing manufacturers to much better fulfill the obstacles of an open market.

Information Analytics and IoT Assimilation

Information analytics and the assimilation of the Internet of Points (IoT) are changing plastic shot molding by giving makers with unmatched insights into their operations. By leveraging real-time information accumulated from interconnected equipments and sensing units, manufacturers can keep track of performance metrics, recognize inefficiencies, and optimize manufacturing procedures. This data-driven method helps with predictive upkeep, lowering downtime and expanding devices lifespan.

In addition, IoT assimilation enables for enhanced quality control. By continually tracking variables such as temperature level, cycle, and pressure times, makers can quickly spot deviations from developed parameters and make changes in genuine time. This not just enhances product uniformity yet likewise lowers waste and scrap prices.

The fusion of information analytics and IoT technologies likewise empowers makers to adopt even more agile production that site approaches. With access to extensive data analytics, companies can reply to market demands with better flexibility, changing manufacturing schedules and setups as required. This flexibility is essential in a quickly transforming manufacturing landscape.

Customization and Design Flexibility

Exactly how can personalization and design adaptability improve the competition of plastic shot molding? Customization permits makers to meet details client needs, fitting distinct measurements, shapes, and capabilities that common products might not fulfill.

Innovations in style modern technologies, such as computer-aided style (CAD) and quick prototyping, additional bolster this pattern. These devices allow developers to create intricate geometries and elaborate patterns, which can be flawlessly integrated into the manufacturing process. Because of this, manufacturers my website can react promptly to altering customer choices and market demands.

Furthermore, the execution of modular tooling systems enhances style adaptability, permitting quicker modifications in between various product styles without considerable downtime. This adaptability can cause lowered lead times and lower manufacturing expenses, making firms more affordable and agile. Ultimately, accepting modification and layout flexibility in plastic injection molding not only raises product offerings yet additionally strengthens market positioning in an ever-evolving landscape.

Conclusion

The future of plastic shot molding is defined by significant developments in automation, lasting techniques, and ingenious materials. Customization via modular tooling and quick prototyping will certainly allow producers to remain affordable and receptive to the dynamic demands of the market.

The future of plastic injection molding is defined by substantial innovations in automation, lasting methods, and cutting-edge products.

Report this page